Job van

Beek’s Opel Corsa-A for Autocross

competition

2005

In 2005 Job started

his career in autocross competition.

In the first year,

he drove a Corsa-a with 1.4 single point injection

engine (C14NZ) and competed in a few local NVACT-competitions, in category O-.

In O- the engine is limited to 1600 cc, and no modifications are allowed to the

engine and transmission.

After a few races,

another competitor finally persuaded Job to weld the differential, so that it

is locked 100%. The other guy did this as well, and drove like this for years

already. He said that it would make a big difference in performance on the

track. “And they never check anyway…..”

We took the

transmission apart, welded up the differential, and put it back together. Just

to give it a try. On the first race, Job won by a big margin. Immediately after

the race, the car was checked by the officials, and of course they found the

locked differential. A disqualification was the result.

For 2006 Job decided

to compete in the NVACT championship, but in S1 category. In this category the

engine is limited to 1300 cc, but modifications inside the engine and

transmission are allowed, as long as the outside of the engine and transmission

is not changed from the original.

As a test Job drove

his Corsa, now equipped with a 13SB engine in the

last few races of 2005.

13SB carburettor engine

2006

In the winter of

2005-2006 the engine was modified to a different camshaft, and also the

Irmscher injection was installed. The control system for the engine was

home-made, and installed in the original housing of the Bosch L-Jetronic, as per the regulations for S1 category.

The transmission was

still the original F10, but of course it had the welded differential installed.

With this car Job

was quite succesfull, and with about half of the

races for the championship over, he was in 2nd place.

During the summer break

we spent many many hours in the workshop, working on the

cylinder head with a Dremel tool.

With this head, the

engine really came alive, and Job won most races in the second half of the

season. At the end of his first full

season, he finished seconds in the championship, just a few points short of

number 1 (another Opel Corsa-A)

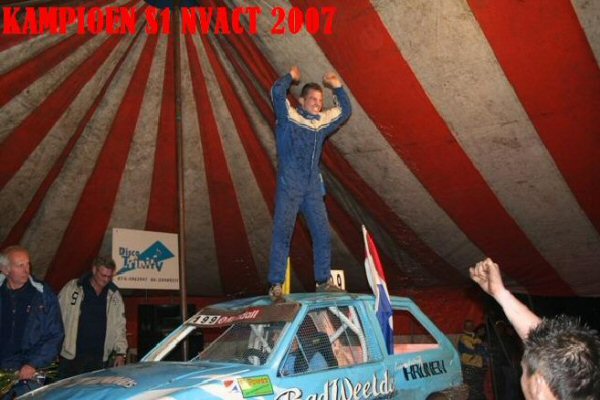

2007

In the winter 2006-2007

a new car was built, but still with the same engine. The engine performed very

well the year before, and was still in good condition.

Old engine in new car

The downside of the

increased performance and the welded differential soon became apparent. The driveshafts

were not up to it, and the wheelside CV-joints kept

breaking. Because of this, Job was losing too many points in the championship.

The decision was

made to install another differential, hoping that it would cure the drive-shaft

problem.

After installing the

other differential, the driveshafts lasted much

longer. Apparently the welded differential put too much load on them.

With the car being

much more reliable, Job won the 2007 championship.

2008

For the 2008 season,

another new car and a new engine were built.

The engine is still

a 1.3 litre and it still uses the original pistons,

connecting rods, crankshaft, etc. The changes are mainly in the

cilinderhead. More hours with the Dremel

tool, and a hotter, but still very much torque-biased camshaft was installed.

Making the roll-cage

After painting

and a new engine

installed.....

The new engine

performance was very good. So good in fact that the gearbox broke every other

race. Back to the drawing board again.

2nd gear teeth are

missing

Hopefully this is stronger

With the new gears

the car proved to be very reliable, and the engine just seemed to run better

and better every race.

Towards the end of

the season there were a couple of failures of the drive-shafts again. The

wheelside CV-joints broke twice within a few races, so we

had to think of something stronger.

After a lot of

thinking and searching for information the decision was made to use

Astra/Kadett 2 litre

wheelside cv-joints. By using a

modified wheelbearing, and modifying the steering

knuckle, these cv-joints could be fitted. On the

gearbox-side we still use the original GSI cv-joints.

The shafts

connecting the cv-joints were cut and welded at the

correct length by a welding specialist. “Don’t worry, they won’t break. The

same welded shafts are used in 1.6 and 2.0 litre

corsa’s and astra’s”. That is

what the specialist assured us.

On the last race of

the season we tested this new set-up, and it seemed to work fine. But during a

short test at home one of the shafts snapped at the weld. To prevent this from

happening again custom shafts were made.

The NVACT-

championship in S1 was won for the second time.

2009

For 2009 the 2008 car

is used, with the same 1.3 litre engine. The only major

change for the new year are different gear ratios.

A new sponsor made

all of this possible.

New sponsor,

www.prinsautogas.com

This year the plan

was to compete in the Belgian NVACT S1 category again, and in

Europokal Class 1 (up to 1.6 litre).

After a few races,

Job decided that he could do with more practice before going to the first

Europokal, so he also decided to compete in NVACT-S2. This

is pretty much the same as S1, only engine size can be 1.6 litres

(1.3 is the limit for S1).

So far in NVACT,

this year the car seems almost unbeatable. All races in S1 were won, in S2 Job

skipped 2 races, but he won all the other races.

In

Europokal the first race was a huge success, on Saturday Job

finish 5th, ad on Sunday 2nd behind a 16 valve Seat

Arosa, but ahead of all the Honda’s and Toyota MR2’s.

In the second race

on Saturday a 6th place was the result,

on Sunday another car hit the front wheel

really hard, the steering rod broke, and other suspension parts were damaged.

No finish.

In the third race

Job decided not to compete because of the very bad track conditions.

Car specifications:

Opel Corsa-A

Engine: 1.3 with

Irmscher injection, home-made ecu

Crankshaft, pistons,

connecting rods: stock 13sb, with minor modifications to the pistons

Rod-bolts: ARP,

modified to fit the Opel connecting rod

Camshaft, valves,

valve springs: top secret

Transmission: F10

4-speed, custom made gears

Gear ratios: top

secret

Final drive ratio:

depends on track

Drive shafts: custom

made

Suspension: Proflex

Fuel: Shell V-Power

100 ( we have to buy in Germany, not available in Holland or Belgium)

Motoroil: Kendall GT-1 20W50 Racing Green